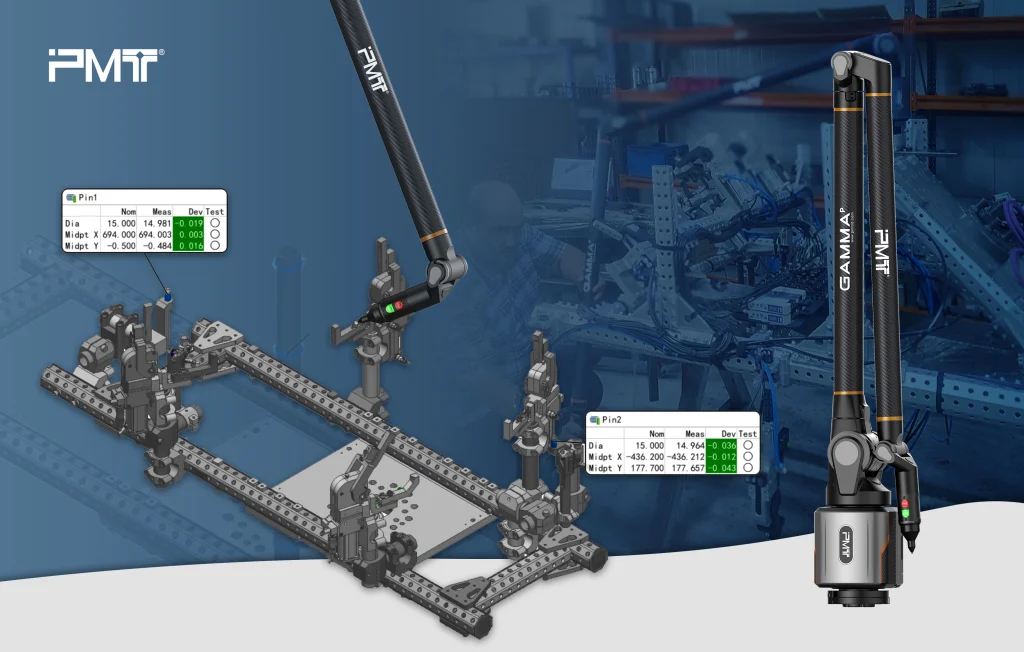

Octagonal tube grippers are widely used in automotive welding and automation industries due to their modular design, high strength, easy assembly, and long lifespan. This case study features a leading automation solutions provider in Turkey, demonstrating how a portable coordinate measuring machine (CMM) ensures comprehensive dimensional inspection of octagonal tube grippers, improving accuracy, reducing lead times, and lowering production costs.